Introduction

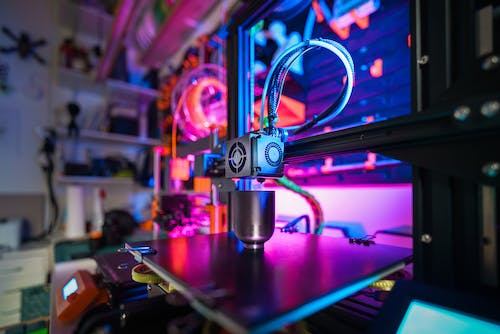

3D printing As a helpful assistant, I am excited to provide you with a detailed analysis of the advantages and disadvantages of 3D printing for businesses and consumers. 3D printing is an innovative technology that has revolutionized the way we create and produce products. It is a process of creating three-dimensional objects by layering materials based on a digital design. This technology has been used in various industries, including healthcare, automotive, aerospace, and consumer products.

Advantages of 3D printing for businesses

One of the significant advantages of 3D printing for businesses is the ability to produce customized products. Traditional manufacturing processes require a significant investment in molds or tooling, making it difficult to produce small quantities of customized products. However, 3D printing allows businesses to produce small quantities of customized products at a lower cost, making it easier to meet customer demands. Another advantage of 3D printing for businesses is the ability to reduce production time. Traditional manufacturing processes require several stages, including design, tooling, and production. 3D printing eliminates the need for tooling, enabling businesses to produce products in a shorter time frame. This accelerated production process can help businesses meet tight deadlines and improve their overall efficiency. Furthermore, 3D printing can help businesses reduce their inventory costs. Traditional manufacturing processes require businesses to produce products in large quantities to achieve economies of scale. However, producing products in large quantities increases inventory costs. 3D printing allows businesses to produce small quantities of products on demand, reducing the need for large inventories.

Disadvantages of 3D printing for businesses

Despite the advantages of 3D printing for businesses, there are also several disadvantages to consider. One of the significant disadvantages is the limited range of materials that can be used in the printing process. Currently, most 3D printers use plastic or metal materials, limiting the range of products that can be produced. This limitation may make it difficult for businesses to produce products that require specific materials. Another disadvantage of 3D printing for businesses is the high cost of equipment and maintenance. 3D printers are expensive, and the cost of maintenance can be significant. Businesses that want to invest in 3D printing technology must be prepared to incur significant upfront costs. Lastly, 3D printing may not be suitable for mass production. While 3D printing can produce small quantities of products efficiently, it may not be suitable for large-scale production. Traditional manufacturing processes are still more efficient and cost-effective for mass production.

Advantages of 3D printing for consumers

3D printing offers several advantages for consumers as well. The most significant advantage is the ability to produce customized products. Consumers can design and create their products, making it easier to get exactly what they want. This customization also enables consumers to personalize products, making them unique and special. Another advantage for consumers is the ability to print replacement parts. Instead of having to purchase a new product, consumers can print replacement parts, saving money and reducing waste. This feature is particularly useful for products that are difficult to find replacement parts for. Lastly, 3D printing can help consumers save money in the long run. While the upfront cost of a 3D printer may be high, consumers can save money by producing products on demand. This feature eliminates the need to purchase products from a store, reducing the overall cost of ownership.

Disadvantages of 3D printing for consumers

Despite the advantages of 3D printing for consumers, there are also several disadvantages to consider. One of the significant disadvantages is the cost of equipment and maintenance. 3D printers can be expensive, and the cost of maintenance can be significant. Consumers must be prepared to incur these costs if they want to invest in this technology. Another disadvantage of 3D printing for consumers is the limited range of materials that can be used in the printing process. Currently, most 3D printers use plastic or metal materials, limiting the range of products that can be produced. This limitation may make it difficult for consumers to produce products that require specific materials. Lastly, 3D printing can be time-consuming. While the production time is shorter than traditional manufacturing processes, the design process can be time-consuming. Consumers must have the necessary skills and software to design their products, which can be a barrier to entry for some.

Applications of 3D printing in various industries

3D printing has several applications in various industries. In the healthcare industry, 3D printing has been used to create prosthetic limbs, dental implants, and surgical models. In the automotive industry, 3D printing has been used to create car parts and prototypes. In the aerospace industry, 3D printing has been used to create lightweight parts for aircraft. In the consumer products industry, 3D printing has been used to create jewelry, toys, and home décor.

Future of 3D printing

The future of 3D printing looks promising. As technology advances, the range of materials that can be used in the printing process is expected to expand, enabling more products to be produced. The cost of equipment and maintenance is also expected to decrease as the technology becomes more widely adopted. Additionally, 3D printing is expected to become more accessible to consumers as the design process becomes more user-friendly.

3D printing technology and equipment

There are several types of 3D printing technology, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Each technology has its advantages and disadvantages, and businesses and consumers must choose the technology that best suits their needs. Additionally, there are several types of 3D printers, including desktop printers, industrial printers, and large-format printers. The type of printer a business or consumer chooses will depend on their production needs and budget.

Cost of 3D printing

The cost of 3D printing varies depending on several factors, including the type of printer, the materials used, and the complexity of the design. Desktop 3D printers can cost anywhere from $200 to $2,000, while industrial 3D printers can cost upwards of $100,000. The cost of materials also varies, with plastic materials costing less than metal materials. The complexity of the design can also affect the cost, with more complex designs costing more to produce.

Conclusion

In conclusion, 3D printing offers several advantages and disadvantages for businesses and consumers. While 3D printing can be costly, it offers several benefits, including the ability to produce customized products, reduce production time, and reduce inventory costs. However, businesses and consumers must also consider the limitations of 3D printing, including the limited range of materials and the high cost of equipment and maintenance. As technology advances, the future of 3D printing looks promising, with the potential to expand the range of materials and make 3D printing more accessible to consumers.

[…] Read More: Advantages and Disadvantages of 3D Printing for Businesses and Consumers […]